There are a variety of ways to supply domestic hot water (DHW) to a home. If you are replacing an existing water heater, using the same type of system that currently exists may or may not be your best option. So, what is the most efficient water heater for your home? There are a lot of things to consider. A professional plumbing or heating contractor will be able to provide a good suggestion based on your home and your needs. You can browse our site for a heating contractor in your area.

The most common types of domestic hot water heaters:

- Tank-style water heaters (electric, gas, or oil)

- Tankless on-demand or “instantaneous” water heaters

- Indirect-fired water heaters connected to a boiler

All water heaters have one job: to heat water that is used for showers, sinks, dishwashers, and washing machines. Water heaters are part of the plumbing system. If your home is equipped with a boiler, the boiler supplies heat to your home through the use of a hydronic system. Boilers are part of the heating system. Water heaters and boilers are two different appliances that serve two separate systems. However, there are boilers designed to produce home heating and hot water. These boilers are known as combi boilers and we will discuss these boilers in a future article.

If your home does not or will not have a hydronic heating system, you are limited to installing either a tank-style unit or a tankless water heater. Tank-style and tankless water heaters have their advantages and disadvantages.

If you do have a boiler and a hydronic heating system, you have the option of installing an indirect-fired water heater that utilizes the boiler as the source of heat. Heating professionals may refer to these water heaters as “indirect” or “sidearm” tanks.

For the sake of this article, we will assume that you have a hydronic heating system and you are weighing the decision to add an indirect tank to your existing heating system or purchasing a tankless water heater in addition to your hydronic system.

Advantages and disadvantages of tankless water heaters

Tankless water heaters, compact in size, take up less space than tank-style water heaters. In fact, due to their small size, tankless water heaters can be mounted on the wall. Also, by providing hot water only when it is needed, tankless water heaters waste less water and eliminate standby losses associated with maintaining a tank full of hot water.

Tankless water heaters, compact in size, take up less space than tank-style water heaters. In fact, due to their small size, tankless water heaters can be mounted on the wall. Also, by providing hot water only when it is needed, tankless water heaters waste less water and eliminate standby losses associated with maintaining a tank full of hot water.

Disadvantages of tankless water heaters include the potential of not having enough hot water for families that take multiple showers and run hot-water consuming appliances simultaneously. Another disadvantage is that electric tankless water heaters require a moderately high electric power draw, creating higher electricity costs. If the tankless water heater is gas-powered, the unit may have a pilot light which can also waste energy. Additionally, like a boiler, tankless water heaters need to be properly vented. Installing a tankless water heater in addition to a boiler means that your installer will need to run an additional gas line and make another wall or ceiling penetration to vent the water heater. Lastly, high-efficiency tankless water heaters require regular maintenance, and produce acidic condensate that must be properly disposed of.

What about indirect water heaters?

Indirect water heaters work in conjunction with the boiler to provide virtually limitless domestic hot water. They have faster recovery rates than competing tank-style water heaters, insuring plenty of hot water when you need it for your active lifestyle.

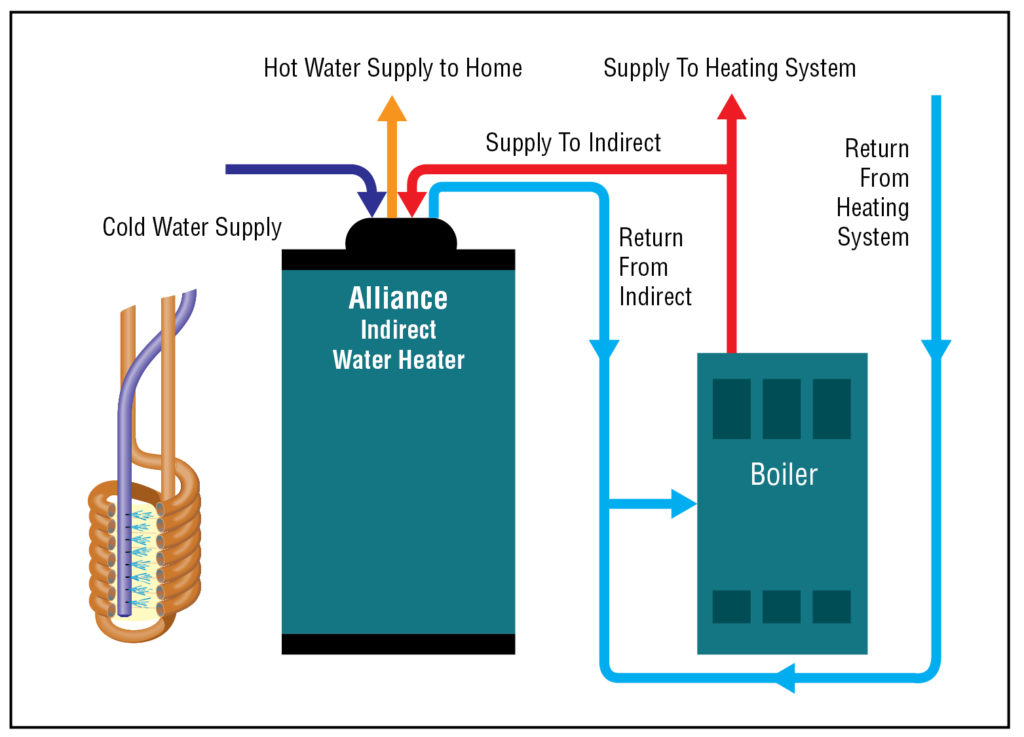

How does an indirect-fired water heater work? It is actually pretty simple. Your boiler heats water and sends it throughout the home in order to heat the house. By adding an extra zone to the hydronic system, the boiler can also send heat to an indirect tank. An indirect tank is essentially a well-insulated vessel with a heating coil inside. Water from the boiler is circulated through the heating coil, which heats the stored water for domestic use. Indirect tanks do not have an electric element and they do not require additional venting.

Installing an indirect water heater is easily accomplished at the time of your boiler installation, or as an add-on option at a later time. You can also add an indirect tank to your boiler system regardless of the fuel your boiler uses. Like all water heaters, indirect tanks come in a wide variety of sizes. Storage capacity is selected based on the quantity of hot water used in the home.

Not all indirect tanks are created equal!

The biggest factors that determine the quality and efficiency of an indirect water heater are A) the ability to resist corrosion and B) the unit’s level of insulation.

The number one enemy of any water heater is hard and/or corrosive water. Water quality across the country varies dramatically, but the poorer the water quality in an area, the shorter the service life a water heater will have.

Whether an indirect tank is well insulated or poorly insulated is a large factor in how efficient the DHW system is. The more insulation on a tank, the less “standby heat loss” it will have, meaning lower energy costs.

The thermoplastic and hydrastone advantage

The ability to withstand corrosion and the need for a high level of efficiency were the two main considerations for U.S. Boiler Company. The Alliance SL and Alliance LT high efficiency indirect-fired water heaters excel in both areas.

The Alliance SL (which stands for stone-lined) was designed and built specifically to combat hard water. The concept of “stone-lined” water tanks is not a new one, and has been successful against corrosion for ages. In New England, a region prone to highly acidic water conditions, stone lined tanks are the norm. Actually, It’s not uncommon to find one in service for 30+ years!

The Alliance SL (which stands for stone-lined) was designed and built specifically to combat hard water. The concept of “stone-lined” water tanks is not a new one, and has been successful against corrosion for ages. In New England, a region prone to highly acidic water conditions, stone lined tanks are the norm. Actually, It’s not uncommon to find one in service for 30+ years!

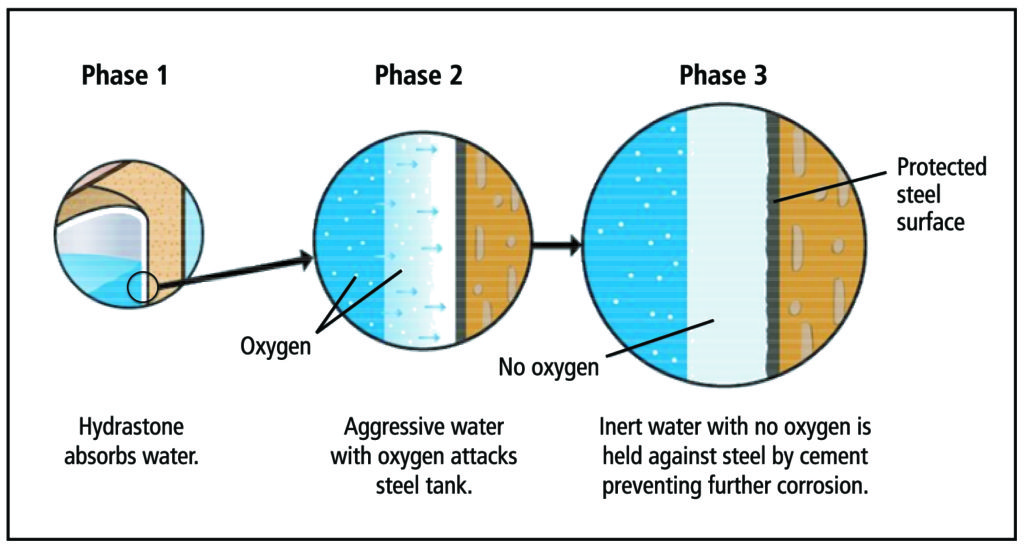

What makes the Alliance SL unique is the Hydrastone-lining itself. This 1/2” tank liner, comprised of a proprietary material similar to cement, protects the outer steel of the tank vessel from the corrosive action of water. When water initially enters the tank, it is absorbed into the Hydrastone-lining permanently. This water loses its oxygen and becomes inert, non-corrosive water, which then acts as a protective wall between the hot water and steel tank. This unique process and design makes Alliance SL water heaters a great choice for domestic hot water applications.

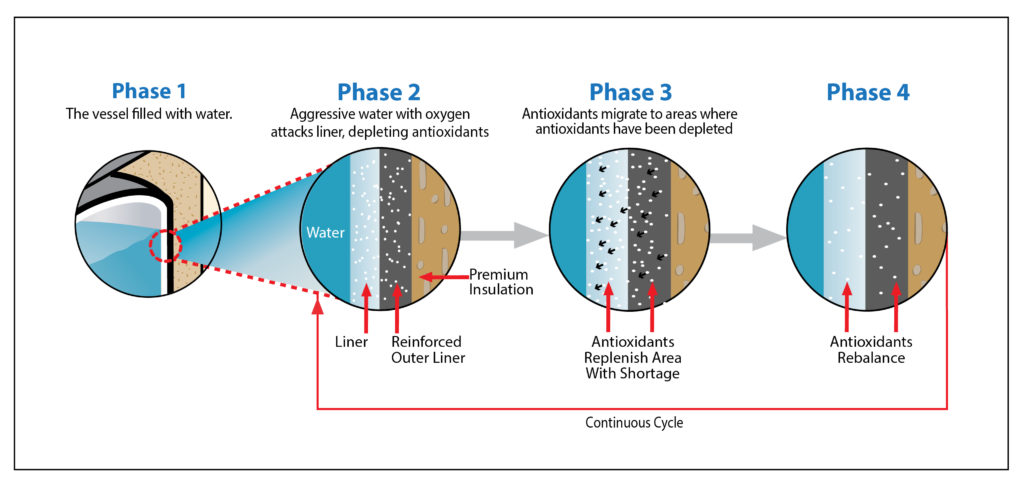

The Alliance LT utilizes a proprietary double-bonded thermoplastic tank liner. The thermoplastic-liner can also handle aggressive water conditions by continuously replenishing and rebalancing antioxidant levels throughout the storage vessel. Thermoplastic construction means that the tank cannot rust, and the double bonded liner assures that the tank will keep performing over its long service life.

The Alliance LT utilizes a proprietary double-bonded thermoplastic tank liner. The thermoplastic-liner can also handle aggressive water conditions by continuously replenishing and rebalancing antioxidant levels throughout the storage vessel. Thermoplastic construction means that the tank cannot rust, and the double bonded liner assures that the tank will keep performing over its long service life.

Hydrastone and thermoplastic-liners make the Alliance SL and Alliance LT so durable that each unit comes with a free 10-year warranty!

Efficiency through insulation

As mentioned earlier, poorly insulated water heaters and indirect tanks give up efficiency through stand-by heat loss. The Alliance SL and Alliance LT use a two-inch layer of dense foam insulation. The thick layer of insulation keeps stand-by heat loss to a minimum saving the end-user significant energy costs!

Further indirect water heater advantages

Unlike many water heaters, the Alliance SL and Alliance LT do not have anode rods, which are typically used to help stop corrosion inside the tank. The use of anode rods can cause tap water to smell like rotten eggs, and these sacrificial rods require regular replacement.

The design of the heating coil inside the Alliance SL and Alliance LT give the water heaters one of the fastest recovery rates in the industry. Fresh water enters the tank from the top via a diffuser that deposits water toward the bottom of the tank. The perforated diffuser shoots cold water in a 360-degree pattern across the heating coil. This puts the coldest water in direct contact with the hottest surface. This unique design has proven to speed up recovery time by more than 15 percent! Fast water movement across the heat coil also diminishes mineral buildup on the coil.

The design of the heating coil inside the Alliance SL and Alliance LT give the water heaters one of the fastest recovery rates in the industry. Fresh water enters the tank from the top via a diffuser that deposits water toward the bottom of the tank. The perforated diffuser shoots cold water in a 360-degree pattern across the heating coil. This puts the coldest water in direct contact with the hottest surface. This unique design has proven to speed up recovery time by more than 15 percent! Fast water movement across the heat coil also diminishes mineral buildup on the coil.

For ease of maintenance, all heat coil connections are located on the top of the tank. Should the coil ever need to be removed for cleaning, it can be pulled from the top of the unit without needing to drain the tank. Ultimately, this will reduce maintenance costs.

The Alliance SL and Alliance LT tanks proudly made in America and offer a long-life, corrosion resistant option for domestic hot water heating. For more information, please reference the product data literature.