The circa-1900 brick mansionettes that line the streets of Landisville, PA, are a remnant of the area’s early prosperity.

At the turn of the century, Landisville was an industrial center surrounded by rich farmland. Grain mills, coal mills, cigar factories, tobacco warehouses and machine shops thrived along a railroad network that connected them to the major population centers of the Mid-Atlantic.

Landisville is still prosperous some 120 years later. The area is experiencing growth in business and housing. As property values increase, many older homes are seeing major investments, aesthetic and otherwise. Contractors in the area – across all the skilled trades – are more than busy.

“We were recently contacted by the owners of one of the many big brick homes in Landisville,” said Dustin Ebersole, owner of High Efficiency Solutions, LLC. “We’ve done work for them in the past, but this time they wanted to make changes in the guest house.”

Above: Once a carriage house, the guest house is heated by a hydronic baseboard system.

Some of the homes in town feature old brick carriage houses, built before Henry Ford invented the Model T. Most owners converted these to garages and storage buildings as the years passed. The client who called High Efficiency Solutions turned their carriage house into a guest suite five years ago.

From coil to combi

The three-story, 1,200-square foot guesthouse features two bedrooms, two bathrooms and a small kitchen. A portion of the ground floor is reserved for storage and mechanical space. The owners are renovating the living spaces to make them more accommodating for visitors staying weeks at a time.

As part of that renovation, the owners wanted to upgrade the heating system. Previously, a U.S. Boiler Company V8 oil boiler served two zones of fin-tube baseboard. The boiler had an internal coil for domestic hot water.

“Space is at a premium here, which is why the original boiler had a hot water coil,” explained Ebersole. “They wanted to convert from oil to natural gas and get rid of the 275-gallon oil tank, which was also in the boiler room. That made the decision to use a U.S. Boiler Company K2 Combi an easy one.”

The owner agreed that the space savings would be welcome, and also liked that there would no longer be a large volume of hot water in the guest house when it’s unoccupied.

“Hydronic work isn’t a huge part of our business, but I really enjoy working on boilers,” said Ebersole. “The industry is changing and that makes it even more exciting.”

Ebersole explained that availability of reliable, efficient combi boilers from an American manufacturer is a relatively new development in the hydronic space. He also noted that ECM pumps have become less price restrictive over the past five years, and the new tools available have made a big difference, too. For example, his company purchased ProPress equipment in 2018 and they haven’t looked back.

While they’ve installed K2 Combis without a single problem, High Efficiency Solutions doesn’t suggest a combi for every hydronic job they get. For many jobs in the area, installation of a condensing combi boiler comes with an additional bonus to the homeowner.

“UGI, our local natural gas utility, offers a $1,500 rebate any time we install a K2 Combi,” said Ebersole. “Installation of a condensing boiler, like the U.S. Boiler Company Alpine, Aspen or K2, usually results in a $1,200 rebate, so there’s a slight advantage with the Combi.”

Ebersole buys U.S. Boiler Product through Dave Raabe, at ROI Marketing, and Hajoca, a supply house he’s worked with since he standardized on U.S. Boiler Company equipment in 2015.

“Jason Richards and Harry Whittaker at Hajoca Lancaster provide world-class support,” said Ebersole.

The combi question

“There are three main factors we consider and discuss with the homeowner before installing a combi boiler,” said Ebersole. “Cost is one of those. A combi boiler will shake out to a lower installed cost than a condensing boiler and indirect tank. If cost is the client’s number one concern, a combi might be a great solution.

Hot water demands are also a big factor. The domestic hot water load in an average American home is generally higher than the heating load. Ebersole explained that in applications with high DHW demands (large homes with big families, bed & breakfasts, etc.), it doesn’t make sense to install a combi system. High Efficiency Solutions has never installed a combi boiler in a home with more than two full bathrooms.

“I always ask about the home’s water use patterns before we install a combi,” said Ebersole. “Combis are great, so long as the client doesn’t require an unusual amount of hot water. I explain upfront that it can take a little longer to get hot water at the tap than it would with a tank-style water heater. As a result, we’ve never had a complaint about it.”

Finally, space is a consideration. Homeowners looking to create more space by removing old mechanical systems are usually fond of the combi alternative. On new construction projects where maximizing floorplans is critical, a combi system can be installed nearly anywhere, including a broom closet.

All around improvement

Once the oil tank in the guest house had been removed, a lateral drilling company arrived to run gas line from the main house to the carriage house. They also installed a spare conduit, through which Ebersole ran a fish tape for pulling future wires/cables. High Efficiency Solutions made the gas connections on either end of the new gas line.

“It’s not common that we connect underground plastic gas line, so I attended some training on how to make Con-Stab connections.”

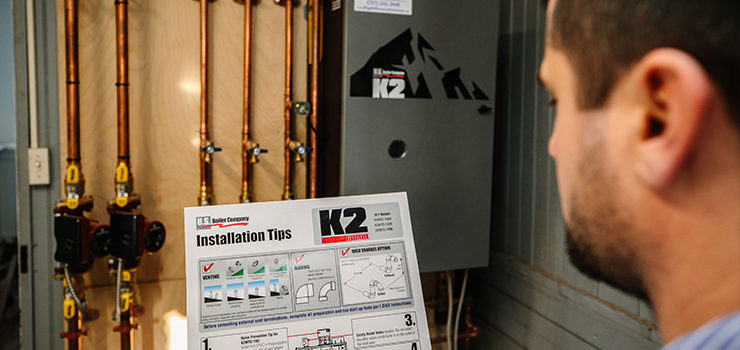

After hanging finish-grade plywood in the mechanical room for near-boiler piping, two technicians installed the K2 Combi and other components.

“We’ve never installed a different combi model because we haven’t had a need to look elsewhere,” said Ebersole. “This one is well built, comes with fantastic installation instructions, and the combustion analyzer port is factory installed in the exhaust pipe. The K2 Combi is also very customizable through its controls, especially in regard to outdoor reset.”

“I like to stick with a brand of equipment until either the manufacturer or the distributor give me a reason to look elsewhere,” he continued. “U.S. Boiler has a great combination of quality, reasonable cost, and great tech support, not to mention a fantastic distributor. I’m usually the one who takes emergency service calls if a system breaks down, so I pick equipment that doesn’t get me out of bed.”

Above: Dustin Ebersole, owner of High Efficiency Solutions, appreciates how easy it is to customize the K2 Combi’s controls, especially in regard to outdoor reset.

Ebersole always checks back with clients after installing any system. The feedback that High Efficiency Solutions receives after installing a K2 Combi usually includes comments about never running out of hot water, and surprise over how quiet the system is, especially when switching from an oil boiler.

“The guesthouse heat loss totaled 48,000 BTU/H, and had been heated with a 105 MBH oil boiler,” explained Ebersole. “We’ve retrofitted with a 135 MBH modulating boiler, so the extra capacity that’s needed to produce DHW does no harm, since the boiler will run at low fire any time there’s a call for space heat. Add to that, the year-round standby heat loss of a high-volume boiler, and I think the owner will see an energy savings of 30 percent, but likely more.”

Last but not least, the retrofit created 40 square-feet of new storage space that had previously been occupied by a larger boiler and oil tank.

Above: High Efficiency Solutions installed a U.S. Boiler Company K2 Combi. Ebersole appreciates the unit’s build quality, easily customizable controls, and simple installation instructions.