In the Hamptons, where some of Long Island’s highest real estate prices are found, custom homes of all sizes line the South Shore.

The well-appointed residences are typically built for extravagant entertaining and large groups of visitors. Numerous bathrooms, lavish soaking tubs and multi-head showers are the rule, not the exception.

“Nine times out of ten, I have to size hydronic systems based on the domestic hot water load, not the home’s heat loss,” said Andrew Bennett, foreman at Harold McMahon Plumbing and Heating Inc. The 15-person company has served The Hamptons and surrounding areas since 1950.

“That’s generally true for condos, too, which we have plenty of,” he continued. “Most of the buildings in this area are older, as is the case in most of New York and New England, so our guys are very efficient at retrofits and our designs are drawn up with consideration for the challenges common to older structures.”

Early this past year, Harold McMahon was hired to replace the boiler system serving a two-story, 64-unit condo co-op in Amagansett, NY, called Ocean Dunes. The oil-fired system that served it was burning 250-gallons per week just to sustain DHW production.

Above: Ocean Dunes is a 64-unit condo co-op that was consuming 250 gallons of fuel oil per week throughout the summer.

The obvious play was to convert the co-op’s heat source to natural gas. Over the years, Bennett has gotten quite good at converting light commercial oil systems to high-efficiency natural gas. Without fail, that recipe includes the use of U.S. Boiler Company’s Alpine condensing boiler.

“I’ve probably installed 100 Alpines,” said Bennett. “Paul McCartney, in fact, owns an Alpine 210 and a 120-gallon Alliance indirect water heater. Because of the Alpine’s size range – from 80 to 800 MBH – we can use them on just about any job we come across.”

Bennett designed the new Ocean Dunes system himself, with Chris McCorvey or Serg Lement at Venco Sales answering any questions that came up along the way. In addition to the boiler system replacement, Harold McMahon was also asked to improve the comfort within the condos, but without re-zoning the building’s baseboard radiation.

Planning for Efficient Expansion

The old system included six, 170 MBH oil boilers, with non-functional staging controls, incorrect pipe sizing and poor placement of all system accessories. Bennett wanted a clean slate. Hammering out the old slab, removing the oil boilers, and running the new gas lines accounted for most of the labor.

In April, Bennett’s design materialized in the basement at Ocean Dunes. Four stainless steel Alpine 210 condensing boilers were installed and staged in rotating lead-lag fashion through the onboard Sage 2.3 boiler control system.

Because of the nature of the DHW load in this facility, Bennett really wanted to optimize boiler performance year-round, not just in the winter.

“That means ensuring long runtimes and sizing the boilers properly,” said Bennett. “But we also wanted to provide extra capacity for the possibility of future expansion. So we installed more capacity than was needed, but we slowed the fan speeds down. For a heating call, each unit only inputs 170 MBH at max firing rate. Of course, the supply water temperature is determined by the Alpine’s outdoor reset control. Our outdoor design temp is 15°F, with a supply water temp of 175°F and a 10°F differential above setting.”

“For a DHW call, the fan speed will increase to 190 MBH,” he continued. “Then, we set up our lead-lag controls at a base rate of 60 percent. I can do all of this through the onboard controls.”

The new modulating boilers provide hot water to indirect tanks totaling 240-gallons. Even during tourist season and peak water use time of day, there’s no way the facility’s call for heat can outpace the system’s ability to provide it.

Above: (L-R) Andrew Bennett, Chase Plachy and Will Dayton take a moment to appreciate their work at Ocean Dunes.

In an effort to improve electric efficiency in addition to fuel efficiency, Harold McMahon technicians Will Dayton and Chase Plachy installed only ECM circulators. Both the old steel mains and the new welded manifolds would have been cause for concern if not addressed properly. The permanent-magnet motors used in hi-efficiency circulators attract ferrous sludge and debris in any system that includes iron components.

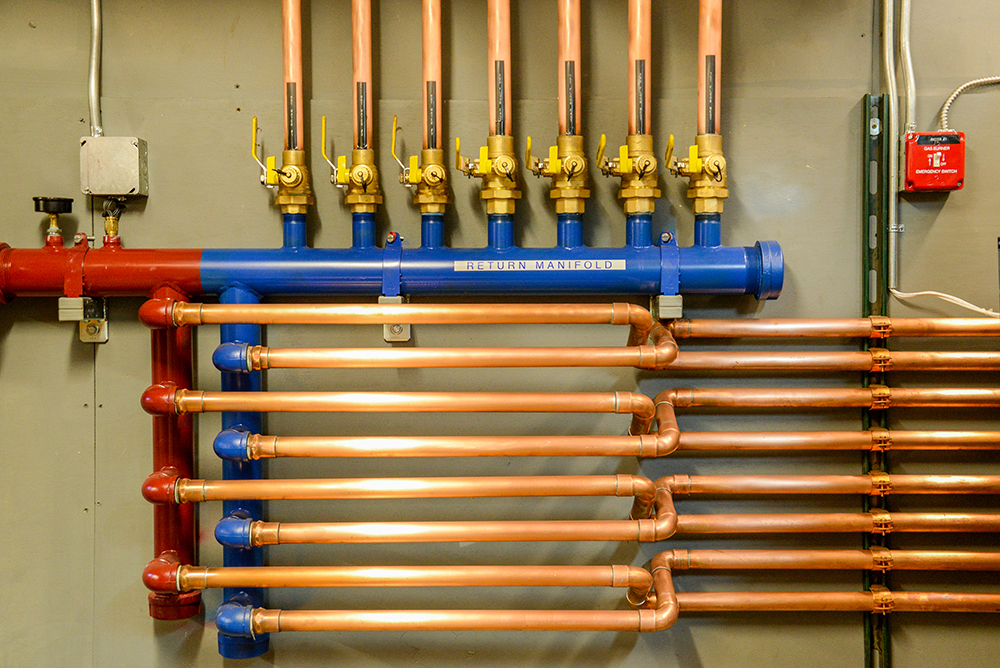

“We included a mag filter on each boiler return,” said Bennett. “That’s not uncommon, because we always use ECM pumps and we generally have our manifolds custom-welded by a fab shop called Earthly Manifolds, in Ridge, NY.”

Insulating pipe, painting manifolds and labeling components was conducted on the last day of the retrofit; day nine. Timers and new pumps were also installed on the two, 300-foot DHW recirculation loops. This way – between the hours of 11:00pm and 5:00 am – the loop isn’t shedding more heat than necessary to standby loss, and the circulators aren’t running without cause.

Above: Harold McMahon Plumbing and Heating Inc. take a lot of pride in their craft, to the point of labelling and color-coding their custom manifolds.

For Consideration

The co-op was, and still is, divided into four zones: two upstairs and two down. A single thermostat serves 16 condos, and is installed at the far end of each floor under a locked cover. Each condo within the zone is at the mercy of that single thermostat. While units on the end of the building have more exterior wall exposure, there’s also far more solar gain on the shore side of the building, creating uneven loads across the zone.

Individually zoning each unit was too invasive of a project, but property managers still want to improve comfort. McMahon proposed installing a wireless thermostat on each zone with up to eight remote air sensors per zone to average temperatures across the 16 rooms on each zone.

“Management at Ocean Dunes is still considering whether or not to install the new thermostat system, which would result in comfort improvements across the whole building,” said Bennett. “But the energy savings were realized even before heating season started. Looking at the Alpine’s control, I can see that the one boiler runs at 20 percent input for 16 hours to maintain DHW. Low input and long runtimes – that is where condensing gas technology shines.”

The numbers tend to agree.

“We compared our mid-April through mid-July oil bills from 2018 to the gas bills from the same timeframe in 2019,” said Jeff Smith, project manager for Ocean Bay Management. “In those three warm months alone, we’ve cut the fuel expenses by roughly $7,000!”