The decision to install a high efficiency, modulating, condensing boiler inevitably leads to some responsibility regarding disposal of condensate. While visiting jobsites to assist contractors, I’ve seen a multitude of ways that condensate is removed from the boiler room to be disposed. The handling of condensate can create concerns due to its corrosive effect. Care has to be taken to ensure that the surfaces condensate comes in contact with are resistant.

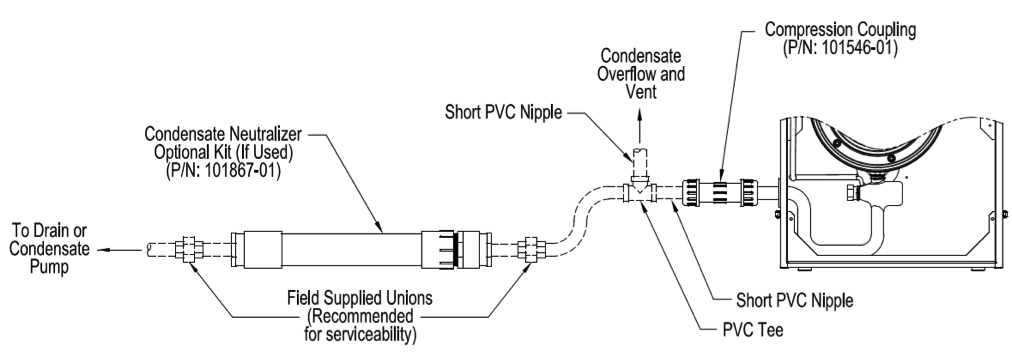

There are two basic strategies to get rid of condensate; the first being gravity, and the second utilizing a pump designed for condensate removal. Both methods require the use of a non-corrosive pipe, such as schedule 40 PVC or CPVC.

When a gravity drain system is used, the drain line is normally run horizontally along the floor. In a perfect situation, the drain line should always pitch downhill. If it cannot pitch downhill, it may run horizontally but must always stay below the trap outlet. It’s a good idea to use a vacuum breaker at the trap (see illustration below).

If the condensate line will need to terminate above the boiler trap, the use of a condensate pump is required. Your distributor will be able to suggest the proper pump for this application, but I usually prefer a condensate pump with an overflow switch that shuts the boiler down if the pump were to fail. This safety switch can be wired to the external limit terminals on the boiler’s low voltage terminal strip. This would show a soft lockout on the boiler, and the open limit string display would show open contacts on external limit directing you to the condensate pump. At U.S. Boiler, we install a condensate trap on our condensing boiler, so the use of a second trap is not recommended because a second trap could create operational problems for the boiler. The termination of the pump must also be installed so the condensate pump tank, tubing, or tube termination can’t freeze.

Condensate has a pH range of 3.5% – 4.5%, making it acidic. Where we terminate the condensate needs to be considered due to its corrosive effect. It can cause damage to, or destroy, many items it comes into contact with. When possible, it’s good practice to run condensate lines in areas where a leak won’t cause property damage. And make no mistake. It’s no joke. I’ve seen situations where multiple boilers draining into the same floor drain have totally destroyed a cast-iron floor drain cap within a couple of years.

An even bigger concern is that old, cast-iron drain and sewer lines are just as susceptible; a big concern in old homes. Although the newer plastic lines will not be affected, the older ones can be. We must also ask ourselves what happens at the wastewater/sewage processing plants, and in on-site septic systems. The pH of wastewater needs to remain between 6 and 9 to protect the microscopic organisms that are so vital to sewage disposal. Acids and other substances that alter pH can deactivate treatment processes when they enter the wastewater plant.

U.S. Boiler Company offers an optional condensate neutralizer filled with limestone chips. The limestone will require replacement over time, determined by a pH test on the condensate leaving the neutralizer. Condensate neutralizers are a simple, inexpensive, yet very effective security measure when you can’t be entirely certain what kind of pipes you’re draining into, or what local codes may dictate.

Ron Beck is Outside Technical Advisor and Manager of Training for U.S. Boiler Company, where he’s been since 1998. Ron’s 34 years of experience in the heating industry include climbing the ranks of aHVAC company, from apprentice to service manager. Ron can be reached at: RBeck@usboiler.net

By Ron Beck, Outside Technical Advisor and Manager of Training for U.S. Boiler Company

By Ron Beck, Outside Technical Advisor and Manager of Training for U.S. Boiler Company