To quote an old country song, “I guess it’s not what you take when you leave this world behind you… It’s what you leave behind you when you go.”

Maybe this concept applies to situations aside from our own mortality. Maybe this thread should follow us through each chapter of our lives; career changes, moving away from old neighborhoods, retirement, personal and business relationships, etc. Did we leave improvements in our wake? Did we give, and not just take?

This thought crossed Bill Buffington’s mind daily as he designed what would become the ultimate hydronic heating system for a large, non-profit facility in rural Pennsylvania. At the project’s culmination on February 23, 2018, he stepped back and gazed at a wall covered in high-efficiency K2 boilers and square piping. In that moment, the notion of a legacy became tangible.

“You only get a few shots at creating a system like this, for a facility like this one,” said Buffington, who owns WM Buffington, Inc. “I hope, someday, our efforts here inspire a young technician to do his very best work.”

WM Buffington Company is a 66-year-old, second-generation company that serves the counties surrounding Harrisburg, PA. They were recently hired to replace the boiler system at a long-abandoned facility in rural Lykens PA, which had recently been purchased by a philanthropist in an effort to battle the poverty that has gripped the region for decades.

A big need

Ivan and Alma Martin bought what is now referred to as The Valley Lighthouse in early 2017. The 20,000 square-foot building, built in the 1930s, has been a car dealership, restaurant, bowling alley and various other things over the years. But it hasn’t been occupied since 2012. All of its mechanical components were burst and completely unsalvageable.

Born into a plain Mennonite family, Mr. Martin left school after completing the 6thgrade and began to self-educate on every topic from advanced medicine to alternative agriculture. He ultimately found his niche in inventing and manufacturing specialty medical equipment. He’s now 80, and has built and sold three multi-million dollar corporations.

After Ivan’s sons sold the last company he had started, they gave him money from the proceeds to start a foundation to help people in need. The Ivan W & Alma E Martin Family Foundation focuses on services that help give people a hand up, not just a hand out. The idea is consistent with “Give a man a fish and he can eat for a day. Teach a man how to fish and he can eat for a lifetime.”

“Our goals include a variety of training courses, workshops, support groups and when possible to help people create their own small businesses,” said Stephen Sands, executive director of The Valley Lighthouse. “But, we aren’t ignoring the needs for more conventional means of assistance.”

“There will also be a food bank, which is different from a typical food pantry in that it’ll offer perishable foods,” continued Sands. “But that takes freezer and refrigerator space. Luckily, The Valley Light house has enough room for a food bank, classrooms,community meeting rooms, a large special event room, and more.”

A big answer

So, The Valley Lighthouse was a building shell the needed improvements. High on the list, a heating system was needed before much of the interior work could begin. Sands knew that he could trust WM Buffington to design and install an efficient, high quality, reliable system.”

By the time Buffington was given a signed contract for the job, the deadline was a mere two weeks away. The new system, which was entirely Buffington’s brainchild, needed to be operational in time for the Martins’ 60th wedding anniversary. The event drew 275 friends and family, and was held in the only room ready to be occupied.

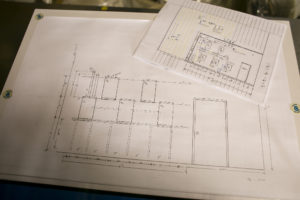

Above: Daave Raabe, at ROI Marketing helped with piping layout, and Bill Buffington’s designs were meticulous.

The design included five, 180 MBH U.S. Boiler K2 condensing boilers, piped and controlled in series, one large, ECM circulator, and a 50-gallon Alliance sidearm tank for DHW. All the boilers would feed a three-inch loop with a large Caleffi hydro-separator/air and dirt eliminator.

The building’s two air handlers – one 530 MBH and one 400 MBH, now outfitted with new hot water coils – would each have a zone valve, and the pressure-sensing circulator would respond accordingly. It’s a beautifully simple system, but the scale was daunting.

“I was ready to dedicate the manpower, but there were two main challenges: getting the parts, and familiarizing ourselves with a new boiler,” said Buffington. “Fortunately, I had an ace up each sleeve.”

Buffington relied on Hajoca’s Lancaster, PA, location to supply all materials. The wholesaler went as far as to have the Grundfos Magna circulator shipped overnight, and had all the K2 boilers in stock.

For help with piping design, specification and startup, Buffington leaned on sales rep Dave Raabe, at ROI Marketing.

A wall of warmth

Within hours of having a signed contract, Buffington technicians were tearing apart the old, frozen sectional boiler that had served the building for nearly 40 years. Meanwhile, others were hanging Unistrut on a block wall and running new pipe to the air handlers.

Above: Together, the five K2 boilers offer a 50:1 turndown ratio, with inputs between 18,000 and 900,000 BTUs. Domestic hot water is supplied by a 50-gallon Alliance SL indirect tank.

The five K2 boilers were hung in two staggered rows. They operate as one large system, each with a 10-to-one turn-down ratio. Combined, the 95% AFUE boilers provide the facility 50-to-one turndown: or the ability to provide inputs from 18,000 to 900,000 BTUs. The fact that each boiler contains its own circulator eliminated a lot of piping and wiring.

“After learning about the K2, the boiler was a natural choice,” said Buffington. “The layout of components inside the cabinet is intuitive, but the controls are really what won me over. I’ve been looking to find a new line of condensing boilers for a while now, and the fact the control panel is universal across all sizes was a big selling point. That’s a luxury I haven’t had since we started installing wall-hung models.”

A time for reflection

“What the Buffington crew was able to accomplish in 11 days is nothing short of amazing,” said Alan Garner, VP and Treasurer of the Ivan W & Alma E Martin Family Foundation. “Their technical aptitude was matched by their ability to explain things in layman’s’ terms. Ivan and I were blown away, and we’d heartily recommend them to anyone.”

Above: A few weeks after completion, Sheldon checks runtime hours across all five boilers. Thanks to its cool burner door design, technicians can more easily operate around a hot heat exchanger.

For Bill Buffington, a moment of reflection came on the last day, right after start-up. Three technicians stood back admiring their work and Bill’s design, taking photos and sending them to friends.

“I’m proud of this, and I’m proud of my guys,” he said. “The fact that our work will serve this facility, this organization and this community for decades is rewarding. It’s what we do at WM Buffington Company, and it’s what keeps me asleep at night.”